0 to 100 “Types of bentonite and their differences”

what will you read...

Definition of BentoniteTypes of Bentonite 1. Sodium Bentonite: The First Type of Bentonite 2. Calcium Bentonite: The Second Type of Bentonite3. Potassium Bentonite: The Third Type of Bentonite 4. Acid-Activated (Activated) Bentonite: The Fourth Type of BentoniteChemical Differences Between Sodium and Calcium BentoniteMethods for Identifying Different Types of BentoniteSuggested Best Methods for Different Types of BentoniteAdvantages and Disadvantages of Different Types of BentoniteBentonite Reserves in the World and IranAnswers to Two QuestionsConclusion

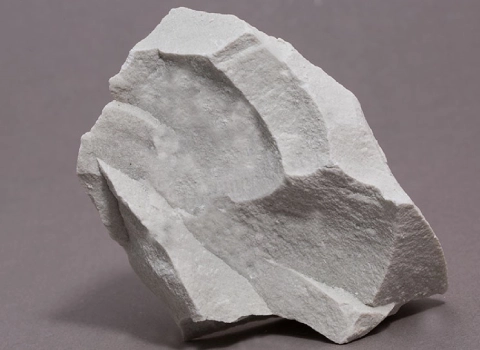

What is Bentonite? Bentonite is one of the key and versatile minerals, widely used across various industries due to its unique chemical and physical properties. It belongs to the clay family and primarily consists of the mineral montmorillonite ((Na,Ca)0.33(Al,Mg)2(Si4O10)(OH)2·nH2O), which has a layered structure. Its properties depend on the exchangeable ions and the proportion of different elements present. This article provides an in-depth exploration of the types of bentonite, their chemical compositions, colors, and applications.

Definition of Bentonite

Bentonite is a mineral clay composed mainly of montmorillonite, a type of smectite clay (Smectite structure: a layered arrangement comprising an octahedral alumina layer sandwiched between two tetrahedral silica layers, with a net negative charge, enabling it to absorb water and cations between layers). It is characterized by high cation exchange capacity and swelling properties. Bentonite forms in specific sedimentary environments, such as volcanic regions. Its chemical composition typically includes oxides of silicon (SiO2), aluminum (Al2O3), magnesium (MgO), sodium (Na2O), and calcium (CaO).

Types of Bentonite

-

1. Sodium Bentonite: The First Type of Bentonite

Sodium bentonite, characterized by the presence of sodium ions in its structure, has high water absorption and swelling capacity, making it one of the most widely used types of bentonite. It contains a high ratio of montmorillonite, constituting about 60-90%

- SiO₂: 55-60%

- Al₂O₃: 15-20%

- Fe₂O₃: 2-5%

- MgO: 1-3%

- Na₂O: 2-5%

Color:

Usually light gray to greenish-gray, depending on the percentage of iron oxide and other impurities.

Characteristics:

- High Swelling Capacity: Can absorb up to 20 times its weight in water.

- Large Surface Area: Around 600-800 m²/g.

- Strong Gel Formation: Exhibits excellent plasticity.

Applications:

- Oil and Gas Drilling: Used as a drilling mud to enhance rheological properties, stabilize boreholes, cool drill bits, and transport cuttings to the surface.

- Sealing and Geotechnical Engineering: In landfill liners and nuclear waste repositories.

- Civil Engineering: For constructing waterproof barriers and sealants.

- Cosmetics Industry: As a component in face masks for impurity adsorption.

-

2. Calcium Bentonite: The Second Type of Bentonite

Calcium bentonite predominantly contains calcium ions, known for its high binding strength and mechanical durability. It is also valued in the food and cosmetic industries for its purifying properties. Unlike sodium bentonite, calcium bentonite has lower swelling capacity but excels in oil and fat absorption.

Typical Chemical Composition:

- SiO₂: 50-55%

- Al₂O₃: 12-17%

- CaO: 2-6%

- MgO: 3-5%

- Fe₂O₃: 3-7%

Color:

Ranges from light gray to light brown, depending on the amount of iron oxide and impurities.

Characteristics:

- Moderate Swelling Capacity: Absorbs 5-8 times its weight in water.

- High Adhesion Strength.

- Superior Mechanical Resistance: More robust than sodium bentonite.

- High Oil Absorption: Ideal for liquid purification and fat removal.

Applications:

- Oil and Liquid Purification: For removing acidic impurities and decolorization.

- Animal Feed: As an additive to reduce toxins and improve digestion.

- Ceramics Manufacturing: As a binder in ceramic glazes.

-

3. Potassium Bentonite: The Third Type of Bentonite

This type of bentonite contains potassium ions and is primarily used in agriculture and the production of chemical fertilizers. Due to its rarity, its applications are relatively limited.

Typical Chemical Composition:

- SiO₂: 50-60%

- Al₂O₃: 10-15%

- K₂O: 2-4%

Color:

Light brown or gray.

Characteristics:

- Low Swelling Capacity.

- Suitable as a soil amendment for agricultural purposes.

-

4. Acid-Activated (Activated) Bentonite: The Fourth Type of Bentonite

Acid-activated bentonite is chemically modified to enhance its adsorption properties. It is produced by treating raw bentonite with acids like sulfuric acid.

Chemical Composition:

- SiO₂: 60-70%

- Al₂O₃: 10-15%

- Fe₂O₃: 2-5%

- SO₃: 1-3% (due to acid treatment)

Color:

White or light yellow.

Characteristics:

- High Surface Area.

- Enhanced Adsorption Capacity for organic and chemical substances.

Applications:

- Oil Refining: For purifying edible and industrial oils.

- Catalysis: As a catalyst in chemical reactions.

Chemical Differences Between Sodium and Calcium Bentonite

| Feature | Sodium Bentonite | Calcium Bentonite |

|---|---|---|

| Swelling Capacity | High | Low |

| Oil Absorption | Low | High |

| Plasticity | Higher | Lower |

| Mechanical Strength | Lower | Higher |

| Dominant Ion | Na⁺ | Ca²⁺ |

| Color | Light Gray | Gray to Brown |

| SiO₂ Content | 55-60% | 50-55% |

| Al₂O₃ Content | 15-20% | 12-17% |

| Main Applications | Drilling, Sealing | Purification, Animal Feed |

Methods for Identifying Different Types of Bentonite

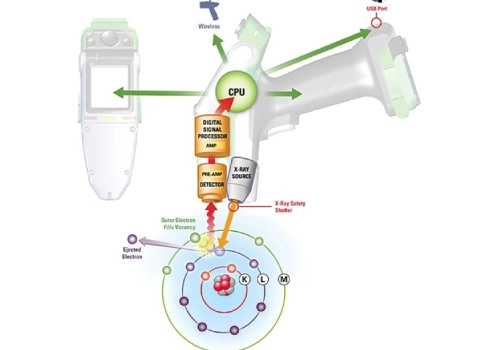

1. XRD Analysis (X-ray Diffraction):

This method is used to precisely determine the crystal structure of montmorillonite and identify the dominant minerals in bentonite. Sodium bentonite, due to its unique crystal structure, exhibits a diffraction pattern distinct from calcium bentonite. XRD analysis is the most reliable option for identifying different types of bentonite in advanced laboratory settings.

2. Chemical Analysis: Measuring the percentages of oxides (SiO₂, Al₂O₃, Fe₂O₃, etc.):

Chemical analysis provides detailed information about the composition of bentonite by measuring the percentages of oxides such as SiO₂, Al₂O₃, and Fe₂O₃. For instance:

- Sodium bentonite typically has a higher percentage of Na₂O.

- Calcium bentonite contains more CaO.

This method is also suitable for identifying minerals on an industrial scale.

3. Swelling Test: Adding water and measuring the change in volume:

In this test, a sample of bentonite is immersed in water, and its volume increase is measured. Sodium bentonite, due to its very high swelling capacity, is clearly distinguishable from calcium bentonite in this test. It is highly recommended for applications in drilling and geotechnical engineering.

4. Ion Exchange Test: Examining the dominant ions (Na⁺, Ca²⁺, or K⁺):

This test involves adding specific chemical solutions to examine the dominant ions in bentonite. For example:

- Calcium bentonite can easily be identified by the presence of Ca²⁺ ions.

This method is suitable for industries such as purification and identifying acid-activated bentonite.

5. Colorimetric Methods: Examining the color of bentonite:

The color of bentonite can provide insights into its impurities. For instance:

- Calcium bentonite is typically light brown to gray.

- Sodium bentonite is lighter gray.

This method is suitable for quick and straightforward assessments at extraction sites.

Reference:

- Alther, G. R. (1986). “The role of clay minerals in industrial applications.” Applied Clay Science, 1(1), 123-137.

- Grim, R. E. (1968). “Clay mineralogy.” McGraw-Hill Book Company.

Suggested Best Methods for Different Types of Bentonite

1. Sodium Bentonite:

- Recommended Methods: Swelling Test and XRD Analysis.

- Reasons: Due to its high swelling capacity, the swelling test is the quickest and most effective method for identification. Additionally, for more precise determination of the crystal structure, XRD analysis is recommended.

2. Calcium Bentonite:

- Recommended Methods: Chemical Analysis and Ion Exchange Test.

- Reasons: Due to its high CaO content and calcium ions, these methods enable more accurate identification. Chemical analysis is effective for determining the overall composition, while ion exchange testing confirms the type of cations present.

3. Acid-Activated Bentonite:

- Recommended Methods: Chemical Analysis and Surface Area Measurement.

- Reasons: This type of bentonite has a high surface area and specific chemical modifications, which can be identified through compositional analysis and adsorption tests.

4. Potassium Bentonite:

- Recommended Methods: Chemical Analysis and XRD.

- Reasons: The presence of potassium in the structure of this bentonite is identified through chemical analysis, while XRD is helpful for determining its crystal structure.

Reference:

- Alther, G. R. (1986). “The role of clay minerals in industrial applications.” Applied Clay Science, 1(1), 123-137.

- Grim, R. E. (1968). “Clay mineralogy.” McGraw-Hill Book Company.

Advantages and Disadvantages of Different Types of Bentonite

Advantages:

- High Absorption Capacity: Ability to absorb water and various chemicals.

- Versatility: Usable across diverse industries.

- Eco-Friendliness: Non-toxic and biodegradable.

Disadvantages:

- High Costs in Certain Applications: Extraction and processing of bentonite can be expensive.

- Limited Natural Resources: Some types of bentonite are only found in specific regions.

Bentonite Reserves in the World and Iran

The largest global reserves of bentonite are found in the United States, China, India, and Turkey. In Iran, significant reserves are located in the provinces of Kerman, Semnan, and South Khorasan. The bentonite extracted from these regions typically has high quality, making it suitable for use across various industries.

Answers to Two Questions

1. What is the main difference between sodium and calcium bentonite?

Sodium bentonite has a higher water absorption capacity and is used in drilling and dam construction, whereas calcium bentonite is primarily used in animal feed and casting industries.

2. Can calcium bentonite be converted to sodium bentonite?

Yes, it is possible through chemical processes.

Conclusion

Thanks to its diverse chemical composition and unique properties, bentonite is one of the most widely used minerals globally. Its various types—sodium, calcium, potassium, and acidic—have distinct chemical compositions and physical characteristics, allowing them to serve a wide range of industries, including drilling, purification, agriculture, and cosmetics. A precise understanding of bentonite’s chemical and physical properties can enhance industrial performance and application.